| Другие настройки | 2 |

In the absence of Process Analytical Technology (PAT), it is necessary to take samples for analysis in the laboratory. When sampling highly potent materials, the operation is usually a challenge both in terms of operator protection and the risk of cross-contamination.

APIs are often stored in double bag barrels. Dec offers a compact and simple sampling solution based on DCS® Drum Containment System for unloading barrels. The mobile system provides a high level of containment (less than 1 µg/m3). Sampling may be carried out in an inert atmosphere.

| Другие настройки | 2 |

Dec develops custom designed insulators for unpacking and/or sampling or for direct loading into process equipment. These systems provide a high degree of tightness and a controlled environment, fast cleaning and drying during product changes.

Depending on the type of input packaging, the isolators can be equipped with an airlock, a rapid transfer port (RTP) or a drum docking system.

Auxiliary equipment such as screens or mills can be integrated depending on the requirements of the process.

| Другие настройки | 2 |

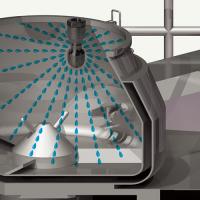

The solution preparation systems of the Korean company Fine FA are a wide range of units of capacitive equipment configurable according to the needs of the process. The reactors are made of AISI 316L, 316Ti, 304 high quality steel and electropolished. Volumes are determined by customer requirements - from 5 to 50,000 liters.

The systems are equipped with all necessary technical solutions: heating and cooling jackets, agitators of various types, weight sensors, CIP automatic washing, nitrogen supply systems, level sensors, ventilation filters, flow meters, sampling systems, special ports.

| Другие настройки | 2 |

| Другие настройки | 2 |

| Другие настройки | 2 |

The R915 Series benchtop machines are ideal for R&D and the biotech industry where small batches are required. The ampoules/vials are manually inserted by the operator into the transport wheel, which moves the objects sequentially to the filling station and on to the capping station.

Filling of ampoules/vials is carried out using rotary piston pumps, providing high dosing accuracy. The design of the machine allows easy integration of peristaltic pumps and a filling system when disposable parts in contact with the product are required.| Производительность | до 1000 объектов (30 мл =1000 ампул в час) |

| Объем наполнения | 0,2 - 30 мл |

| Габариты (Ш x В x Г мм.) | 2250x1500x785 |

| Тип сосуда | с рубашкой |

| Рабочий объем сосуда | 50 л (доступны другие объемы) |

| Типы мембарн | керамические |

| Давление жидкости | 25 бар (нф/оо) |

| Температура | 45 °c (нф/оо) |

| Производительность | 3000 |

| Диаметр объекта | до 52 мм, (другие диаметры по запросу) |

| Диапазон заполнения | 0,2 - 100 мл |

| Высота объекта | до 100 мм, (другие высоты по запросу) |

| Количество станций | Processing machine for pre-sterilised syringes |

Flexible insulators provide protection with a special film that is installed on the frame, which allows you to keep the desired shape. The film can flex with the sleeve, allowing greater mobility and a higher level of ergonomics.

DEC flexible insulators can be used for both toxic and sterile processes. Unlike hard sheath insulators, they can be easily disassembled and require less storage space.

Main advantages: low cost, ergonomics, adaptability and safety.

| Другие настройки | 2 |