The MPTS can be provided as a portable version to take samples from different equipment at different locations. The control panel and MPTS are mounted on a trolley, and the flexible powder hose can be directly connected to the sampling equipment. The system only needs to be connected to vacuum, compressed air and, if required, nitrogen if sampling is to be carried out in an inert atmosphere.

The RINA Serie 200 models are vertical industrial batch centrifuges with manual discharge designed for the separation of solid and liquid suspensions at high speeds.

| Ø барабана (мм) | 700 |

| Высота корзины (мм) | 350 |

| Толщина массы макс. (мм) | 105 |

| Объем массы макс. (Лт.) | 68 |

| Максимальный вес массы. (кг) | 85 |

| Площадь фильтрации (м2) | 0,77 |

| Скорость (об / мин) | 2275 |

| G-фактор макс. (G) | 2000 |

| Вес центрифуги (кг) | 1950 |

| Размеры ШxДxВ (мм) | 1200x1450x1250 |

Characteristics

Lyophilization processes require good design and high performance containment systems. Dec also offers automated loading and unloading solutions for freeze drying systems. With our modular design approach and in-depth knowledge, we offer fixed or flexible loading solutions for any pharmaceutical freeze dryer, including the appropriate holding and handling equipment. The range of modular equipment includes manual systems, semi-automatic as well as fully automated loading and unloading solutions. These systems are designed to efficiently transport vials from the aseptic liquid filling line to the lyophilizer and on to the capper. Our equipment is designed to minimize the risks of contamination and withstand all conditions

As an option for the PTK High Speed Mixer, the liquid binder is contained separately in its own tank and fed into the spray nozzle. The speed of the pump is controlled by an inverter or compressed air, which regulates the fluid flow.

The RT Series Cap Screwing Machines are designed to compensate for potential loss of torque after induction sealing and to re-tighten caps prior to label application with controlled torque applied.

| Другие настройки | 2 |

| Размеры | 2500 (Д) x 700 (Ш) x 1700 (В) мм. |

| Вес нетто | 480 кг |

| - Производительность | Макс. 120 банок в минуту |

| Размеры банок | диаметр 30-100 мм, высота 40-200 мм |

| Размер крышки | диаметр 30-100 мм |

Characteristics

With the help of the RT-F1300N rotary table, round shapes can be dispensed conveniently into hard-to-reach places. Easily adjustable, tiltable Z-axis provides controlled, fixed-angle dosing rotation. For example, the material to be dosed may be applied to a vertical inner or outer wall of a cylindrical component. The turntable is used for dosing adhesives, silicones, greases and lubricants and is fully programmable in terms of speed, wheel diameter, cycle and dosing time. VIEWEG's wide range of accessories allows the installation of cartridges and valves in the Z direction. VIEWEG also offers a range of dispensers, valves and valve controllers. We will be happy to advise you.

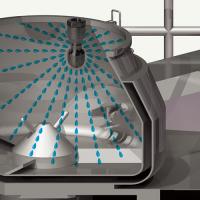

CIP rack and nozzles are an option for the PTK high speed mixer. High pressure water is sprayed through specially placed jets to clean the inside of the tank. The nozzles are easy to remove and reassemble.

The Hanningfield Uni-Dust centrifugal precipitator is specifically designed to recover waste powder from in-house pharmaceutical processes such as compression and encapsulation, typically capturing 90 to 99.9% of waste powder. - Highly efficient design covering 90 - 99.9% - Prevents clogging and replacement of expensive filters in a central vacuum system or vacuum cleaner - Improved lot alignment and product recovery - Virtually zero maintenance costs with no moving parts or filters - Reconstituted powder can be re-introduced - minimizing material wastage and saving money

| Прибл. вес | 40 кг |

| Контактирующие c продуктом детали | нержавеющая сталь 316L |

| Не контактирующие с продуктом детали | нержавеющая сталь 304 |

| Диаметр корпуса циклона | 203.2 мм |

| Диаметр впускной/выпускной трубы | 101.6 мм |

| Диаметр выхода продукта | 139.7 мм |

Characteristics

SafeDock System The patented SafeDock solution is a revolutionary system that greatly simplifies and speeds up the docking operation while guaranteeing a very high level of tightness. The SafeDock consists of a docking tube with a CLS Continuous Liner side port for removing liners and an automatic cap on the piston to completely seal the system. The spout of the big bag is hermetically sealed to the station using a disposable ring, which is removed along with the remaining liner.

Hanningfield Uni-Vac vacuum conveyors are designed as a safe and convenient way to transport powder. - Automate and speed up the loading process - Dust-proof transfer of material from A to B - Reduced manual handling (horizontal and vertical transfer) - Can be installed in line for subsequent feeding (gravity feeding or vacuum pumping)

| Объем | Емкость бункера: 20 литров |

| Контактирующие c продуктом детали | нержавеющая сталь 316L |

| Не контактирующие с продуктом детали | нержавеющая сталь 304 |

| Диаметр бункера | 254 мм |

| Высота бункера | 840 мм |

| Стандартный диаметр шланга | 1.5 дюйма |

Characteristics

Dec offers a range of filling solutions for the pharmaceutical and other industries from semi-automated to fully automated systems. Customized to meet all specific sterile primary packaging needs, our filling solutions are cGMP compliant and provide accurate filling for both liquids and solids. Dec filling equipment can be integrated into your production lines and designed to accommodate a variety of containers including jars, vials, cartridges, syringes and DCS. Fully automated aseptic production plant for filling double chamber syringes with powder and liquid. The active substance and diluent are stored in two separate chambers and are mixed shortly before administration.

IST Series induction sealers use a non-contact metal layer heating method to seal plastic and glass containers.

Sealing occurs after the filling and closing of the cans, which are then transported by a conveyor under the electromagnetic field generated by the Trueseal induction sealing head. A current is induced in the foil layer and heats it up; the heated foil melts the polymer, thereby sticking to the neck of the container.| Другие настройки | 2 |

| Размеры | 2500 (Д) x 710 (Ш) x 1940 (В) мм. |

| Вес нетто | 200 кг |

| - Производительность | Макс. 200 банок в минуту в зависимости от выходной мощности и скорости конвейера |

| Размеры банок | диаметр 30-100 мм, высота 40-200 мм |

| Размеры крышки | диаметр 20-60 мм |

Characteristics

Diagnostics allows you to actively manage your health. Analysis of tissue, blood, or other patient samples by immunomagnetic separation or other methods provides important information about the disease. Currently, diagnosis is not only a stepping stone to therapy; the goal is to prevent the progression of the disease or even its outbreak. In disease control, diagnosis is an integral part of medical decision making, from prevention to monitoring. Dec designs custom aseptic filling/finishing solutions, including an isolation system to house the process if required. Our patented microdosing powder technology provides highly accurate filling with a tolerance of 1% RSD for volumes as low as 1mg, whereas the new BoMa technology has been developed to provide an efficient solution to fluids to solve the problems of speed, accuracy and flexibility. collided with the current pumps. Dec also offers efficient raw material handling and dosing systems and solids preparation. For a recent project, Dec designed two separate raw particle filling lines to avoid cross-contamination. The issuance takes place in our Isocharge system. (OEL <100 µg/m3). This raw material production process includes dosing, mixing, sampling and packaging. Left: Isocharge system with integrated PTS Powder Transfer System® For a recent project, Dec designed two separate raw particle filling lines to avoid cross-contamination. The issuance takes place in our Isocharge system. (OEL <100 µg/m3). This raw material production process includes dosing, mixing, sampling and packaging. Left: Isocharge system with integrated PTS Powder Transfer System® For a recent project, Dec designed two separate raw particle filling lines to avoid cross-contamination. The issuance takes place in our Isocharge system. (OEL <100 µg/m3). This raw material production process includes dosing, mixing, sampling and packaging. Left: Isocharge system with integrated PTS Powder Transfer System®

PAT contributes to a better understanding of the process by measuring critical quality attributes. Dec mainly uses Process Analytical Technology in conjunction with the PTS Batchmixer® for powder mixing or microdosing applications. PAT blending can be used to check in-line blending efficiency with a real-time NIR spectrometer that is installed in the circulation line. The technology is not intrusive, will not disturb the circulation of the powder and does not add cleaning problems. The end point of mixing can be determined using the standard deviation of the movable block without prior calibration. Microdosing - Built-in Powder Sensor Built-in weight measurement is an important advantage when there is a problem with scale integration or response time. Dec can provide a non-contact sensor based on microwave technology that can instantly measure weight and percent relative humidity. The sensor is installed directly at the outlet of the dosing unit. The measurement is not intrusive and gives an instant response.

The patented PFL Powderflex provides continuous and accurate dosing of small to medium quantities of powder, whether controlled loading of powders in continuous production processes or dosing of predetermined accuracy is required. This technology was originally developed for plasma and spray coatings, but is currently used in many areas. PFL extracts powder from any container and transports it over long distances. Its simple design ensures minimal maintenance, making it easy to quickly replace the product. The characteristics of the powder during transfer do not change. PFL is to powder what a peristaltic pump is to liquids. The system consists of two small calibrated chambers, each equipped with a flat filter at the top. A virtually continuous powder flow or precise volumetric dosing is ensured by a unique valve system. The combined action of vacuum and pressure alternately fills and empties the chambers at high frequency. The transmission rate can be easily adjusted by changing the chamber volume or changing the frequency.

UA series models are designed for jar orientation and double cleaning with filtered and ionized air.

Oriented cans are picked up by a side belt conveyor and discharged from the machine in a vertical position. Different can sizes do not require the installation of format parts, and dropped and overturned objects are rejected for continuous operation of the line.| Другие настройки | 2 |

| Размеры | 3200 (Д) x 1200 (Ш) x 1900 (В) мм. |

| Вес нетто | 1050 кг |

| - Производительность | Макс. 200 банок в минуту в зависимости от формы и размера банки |

| Размеры банок | диаметр 30-100 мм, высота 40-200 мм. |

Characteristics

Big Bag, Drum and Carton Filling If you are handling multiple packages, Dec can help provide one single multi-pack filling station that handles FIBCs, drums, cartons, etc.). This system can be equipped with various docking systems depending on the required level of tightness. It can also be equipped with both an interchangeable platform and a support frame adapted to the type of packaging, as well as a multi-scale system adapted to the filling weight.

Hanningfield Uni-Vac vacuum conveyors are designed as a safe and convenient way to transport powder. - Automate and speed up the loading process - Dust-proof transfer of material from A to B - Reduced manual handling (horizontal and vertical transfer) - Can be installed in line for subsequent feeding (gravity feeding or vacuum pumping)

| Объем | Емкость бункера: 5 литров |

| Контактирующие c продуктом детали | нержавеющая сталь 316L |

| Не контактирующие с продуктом детали | нержавеющая сталь 304 |

| Диаметр бункера | 270 мм |

| Высота бункера | 600 мм |

| Стандартный диаметр шланга | 1.0 / 1.5 дюйма |

Characteristics

Magnesium is supplied from a separate rack. The rack consists of a magnesium hopper and a control cabinet. Rollers are used to facilitate movement. Magnesium is supplied to the spray block, which is installed at the base of the feeder.

Hanningfield Uni-Vac vacuum conveyors are designed as a safe and convenient way to transport powder. - Automate and speed up the loading process - Dust-proof transfer of material from A to B - Reduced manual handling (horizontal and vertical transfer) - Can be installed in line for subsequent feeding (gravity feeding or vacuum pumping)

| Объем | Емкость бункера: 10 литров |

| Контактирующие c продуктом детали | нержавеющая сталь 316L |

| Не контактирующие с продуктом детали | нержавеющая сталь 304 |

| Диаметр бункера | 450 мм |

| Высота бункера | 1000 мм |

| Стандартный диаметр шланга | 1.5 дюйма |

Characteristics