Removes external dust from finished capsules and transports them upwards for discharge into the product container.

| Размеры машины [мм] | 500 x 800 x 2,218 |

| Параметры источника питания | 220/380 В перем. тока, 3 фазы, 50/60 Гц |

| Вес машины [кг] | 340 |

| Мощность привода [кВт] | 0,4 |

| Макс. производительность [капсул/час] | 420,000 |

| Параметры элементов управления | 24 В постоянного тока |

Characteristics

The PFB series is rated at 12 bar to protect the user in the event of an explosion. An explosion proof valve (QASV) is also installed on the inlet and outlet ports. It provides a safe environment even with explosive flames and pressures.

As an option for the PTK tablet coater, the Hepa filter is equipped with a heat exchanger or dust collector and the air is filtered up to 99.9% (EN 1882 H13). There is also a pressure gauge to indicate when the filter needs to be cleaned/replaced.

The double jacket is an option for the high speed PTK mixer. The container has a double jacket. Water or steam is supplied to the wall cavity to control the temperature of the container.

IFH is an option for the PTK tablet press, an intermediate powder hopper that is mounted on top of the PTK machine. This option is useful where powders require additional agitation before entering the powder feed tube.

Provides safe handling and easy transport of detachable turrets for installation, removal or maintenance.

Pneumatic cylinder opening of the tank lid is an option for the PTK high speed mixer. The container lid is automatically lifted by an air cylinder at the touch of a button.

The rotary actuator, controlled by compressed air, precisely regulates the air flow to the coater by changing the position of the damper.

The PTK Tablet Press Calibration Kit option allows you to calibrate the load cells installed on the PTK machine. The kit includes some elements for mounting the load cell and a certificate of conformity to national calibration standards.

The metal detector is an option for the PTK tablet press. Most pharmaceutical tablets and capsules can be tested in the MET 30+ with an aperture size of 95mm W x 38mm H, providing calibrated sensitivity of 0.3mm Fe, 0.35mm Nfe and 0.5mm SST. 316 steel. For smaller products (typically no larger than 8 mm diameter), the MET 30+ can also be used with dimensions of 95 mm W x 22 mm H, providing an efficiency of 0.25 mm Fe, 0.3 mm Nfe and 0.39 mm StSt 316

The capsule polisher is an option for the PTK capsule filling machine. Dust on manufactured capsules can be removed with this capsule polishing machine.

The PTK torque motor replaces the traditional belt driven motor and gearbox. This reduces heat generation and noise. Additional heat reduction is possible by selecting a water-cooled motor with intermittent water supply. The volume of water supply must be prepared at the customer's site.

The PTK tablet press option with an open feeder is designed for pellets with good fluidity or for those materials that are not fed efficiently through a mechanical feeder (force feed). Switching between mechanical feeder and open feeder is easy. Both types of feeders use the same hopper.

The flexible and modular Kraemer UTS tablet testing system fully automatically measures the weight, thickness, diameter and hardness of round tablets, oblong tablets, capsules and similar products. The system can be stand-alone or connected to a machine. When connected to the machine, the sampling device will send control signals to the PTK machine to control the machine settings.

As an option for the PTK High Speed Mixer, the liquid binder is contained separately in its own tank and fed into the spray nozzle. The speed of the pump is controlled by an inverter or compressed air, which regulates the fluid flow.

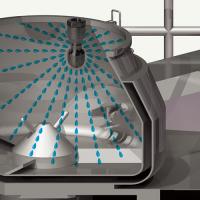

CIP rack and nozzles are an option for the PTK high speed mixer. High pressure water is sprayed through specially placed jets to clean the inside of the tank. The nozzles are easy to remove and reassemble.

Magnesium is supplied from a separate rack. The rack consists of a magnesium hopper and a control cabinet. Rollers are used to facilitate movement. Magnesium is supplied to the spray block, which is installed at the base of the feeder.

The WIP system is an option for the PTK tablet coating machine. The WIP (Wash In Place) system automatically cleans every part of the coater. 5 nozzles are equipped to clean the inside/outside of the coating drum and the air intake/exhaust lines.

Cone Mill (Independent Type) The cone mill is installed directly below the product discharge point, which allows the product to be ground to a specified size when discharging by selecting the correct sieve type. -Servo motor control for driving part -Compact structure with built-in servo motor -Easy and fast touch screen operation -Monitoring of current position and torque values on screen with graphical display -Providing screens of various types and sizes, including screens for wet and dry granulation. -Easy connection for wet or dry grinding mill together with vacuum conveyor and hopper