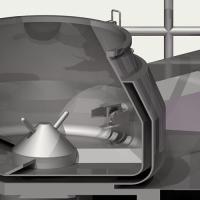

Tank lamp is an option for the PTK High Speed Mixer. There is an LED light on the lid of the jar to check the powder while mixing. This lamp is also useful when the operator is checking the powder through the window on the machine. It is semi-permanent and the lamp cover can be removed separately. Thus, cleaning and maintenance are simplified.

Wet grinding of agglomerates after mixing or sizing of dry granules after fluid bed drying can be performed using the same mill. Screens are available in various sizes and geometries. The cone mill is available as an integrated system or a stand-alone type.

The double jacket is an option for the high speed PTK mixer. The container has a double jacket. Water or steam is supplied to the wall cavity to control the temperature of the container.

Pneumatic cylinder opening of the tank lid is an option for the PTK high speed mixer. The container lid is automatically lifted by an air cylinder at the touch of a button.

As an option for the PTK High Speed Mixer, the liquid binder is contained separately in its own tank and fed into the spray nozzle. The speed of the pump is controlled by an inverter or compressed air, which regulates the fluid flow.

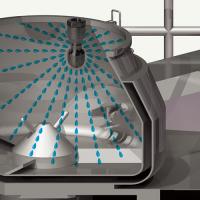

CIP rack and nozzles are an option for the PTK high speed mixer. High pressure water is sprayed through specially placed jets to clean the inside of the tank. The nozzles are easy to remove and reassemble.

Agitator impeller lift is an option for the PTK high speed mixer. After the WIP process, the air cylinder raises the impeller to facilitate drying.